I-resin yokushintshanisa i-anion enamandla

I-resin yokushintshanisa i-anion enamandla

Izinhlaka Zama-Anion Base ezinamandla

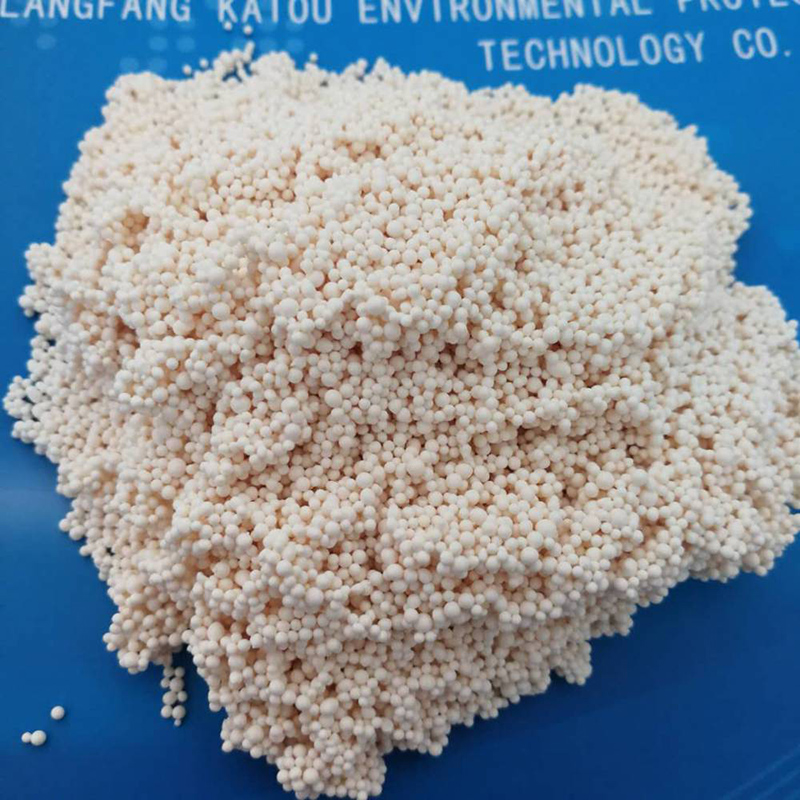

| Izinhlaka | Isakhiwo sePolymer Matrix | Ukubukeka Kwefomu Lomzimba | UmsebenziIqembu |

I-Ionic Ifomu |

Ingqikithi Yokushintshaniswa Komthamo meq / ml | Umswakama Okuqukethwe | Usayizi wezinhlayiyana mm | UkuvuvukalaCl→ OH Max. | Ukuthumela Isisindo g / L |

| I-GA102 | Uhlobo lwe-Gel I, i-Poly-Styrene ene-DVB | Sula ku-Slight Yellow Spherical Ubuhlalu | I-R-NCH3 |

Cl |

0.8 | 65-75% | 0.3-1.2 | 20% | 670-700 |

| I-GA104 | Uhlobo lwe-Gel I, i-Poly-Styrene ene-DVB | Sula ku-Slight Yellow Spherical Ubuhlalu | I-R-NCH3 |

Cl |

1.10 | 55-60% | 0.3-1.2 | 20% | 670-700 |

| I-GA105 | Uhlobo lwe-Gel I, i-Poly-Styrene ene-DVB | Sula ku-Slight Yellow Spherical Ubuhlalu | I-R-NCH3 |

Cl |

1.30 | 48-52% | 0.3-1.2 | 20% | 670-700 |

| I-GA107 | Uhlobo lwe-Gel I, i-Poly-Styrene ene-DVB | Sula ku-Slight Yellow Spherical Ubuhlalu | I-R-NCH3 |

Cl |

1.35 | 42-48% | 0.3-1.2 | 20% | 670-700 |

| I-GA202 | Uhlobo lwe-Gel II, i-Poly-Styrene ene-DVB | Sula ku-Slight Yellow Spherical Ubuhlalu | I-RN (CH3)2(C2H4OH) |

Cl |

1.3 | 45-55% | 0.3-1.2 | 25% | 680-700 |

| GA213 | Ijeli, iPoly-Acrylic ene-DVB | Sula ubuhlalu obuyindilinga | I-R-NCH3 |

Cl |

1.25 | 54-64% | 0.3-1.2 | 25% | 780-700 |

| MA201 | Uhlobo lweMacroporous I Polystyrene ene-DVB | Opaque Ubuhlalu | I-Quaternary Ammonium |

Cl |

1.20 | 50-60% | 0.3-1.2 | 10% | 650-700 |

| MA202 | IMacroporous Type II Polystyrene ene-DVB | Opaque Ubuhlalu | I-Quaternary Ammonium |

Cl |

1.20 | 45-57% | 0.3-1.2 | 10% | 680-700 |

| MA213 | IMacroporous Poly-Acrylic ene-DVB | Opaque Ubuhlalu | I-R-NCH3 |

Cl |

0.80 | 65-75% | 0.3-1.2 | 25% | 680-700 |

Izinyathelo Zokuqapha Ezisetshenziswayo

1. Gcina inani elithile lamanzi

Ion resin resin iqukethe inani elithile lamanzi futhi akufanele igcinwe emoyeni ovulekile. Ngesikhathi sokulondolozwa nokuthuthwa, kufanele igcinwe inomswakama ukugwema ukomiswa komoya nokuphelelwa amandla kwamanzi, okuholela ekwephukeni kwe-resin. Uma i-resin ingenamanzi ngesikhathi sokugcina, kufanele ifakwe emanzini anosawoti agxilile (25%), bese ihlanjululwa kancane kancane. Akufanele ifakwe ngqo emanzini, ukuze kugwenywe ukwanda okusheshayo nocingo oluphukile.

2. Gcina izinga lokushisa elithile

Ngesikhathi sokugcinwa nokuthuthwa ebusika, izinga lokushisa kufanele ligcinwe ku-5-40 ℃ ukugwema ukugcwala ngokweqile noma ukushisa ngokweqile, okuzothinta ikhwalithi. Uma ingekho imishini yokushisa eshisayo ebusika, i-resin ingagcinwa emanzini anosawoti, futhi ukuminyana kwamanzi anosawoti kunganqunywa ngokuya ngezinga lokushisa.

3. Ukususwa kokungcola

Imikhiqizo yezimboni ye-ion exchange resin imvamisa iqukethe inani elincane le-polymer eliphansi nelingasebenzi, kanye nokungcola okungaphili okunjenge-iron, lead kanye nethusi. Lapho i-resin ixhumana namanzi, i-asidi, i-alkali noma ezinye izixazululo, izinto ezingenhla zizodluliselwa kusixazululo, sithinte ikhwalithi yamanzi angcolile. Ngakho-ke, i-resin entsha kufanele yenziwe ngaphambi kokusebenzisa. Ngokuvamile, amanzi asetshenziselwa ukwenza i-resin ikhule ngokugcwele, bese kuthi, ukungcola okungaphili (ikakhulukazi izinhlanganisela zensimbi) kungasuswa ngo-4-5% thela i-hydrochloric acid, futhi ukungcola okungokwemvelo kungasuswa ngo-2-4% thela i-sodium hydroxide Isixazululo. Uma isetshenziselwa ukulungiswa kwemithi, kufanele ifakwe ku-ethanol.

4. Ukwelashwa okusebenzayo njalo

Ukusetshenziswa, i-resin ingavinjelwa ekuhlanjululeni kancane kancane ngensimbi (njenge-iron, ithusi, njll.) Uwoyela nama-molecule we-organic. I-resin ye-anion kulula ukuthi ingcoliswe yizinto eziphilayo. Ingamanziswa noma ihlanzwe nge-10% NaC1 + 2-5% NaOH isixazululo esihlanganisiwe. Uma kunesidingo, ingafakwa ku-1% isisombululo se-hydrogen peroxide imizuzu embalwa. Ezinye izindlela zingasetshenziswa, njengokwelashwa okuhlukile kwe-acid alkali, ukwelashwa kwe-bleaching, ukwelashwa kotshwala nezindlela ezahlukahlukene zokuvala inzalo.